OVERVIEW

The rapid development of green cement and cement-based building materials is pushing manufacturers to seek new and improved methods of production. Mixing has a direct correlation to the performance, strength and durability of specialty cement and composites.

There has been more than 100 varieties of cement till now. In addition to the ordinary Portland cement, there are many other types of special cement, such as white cement, colored cement, rapid hardening cement, low heat cement, etc. They are produced by adding different materials in the process of clinker grinding, such as blast furnace slag and fly ash. Different products vary in the ways they are handled, formed and finished, but at the heart of the process is the mixing procedure, which commonly takes place in ribbon mixers.

APPLICATION

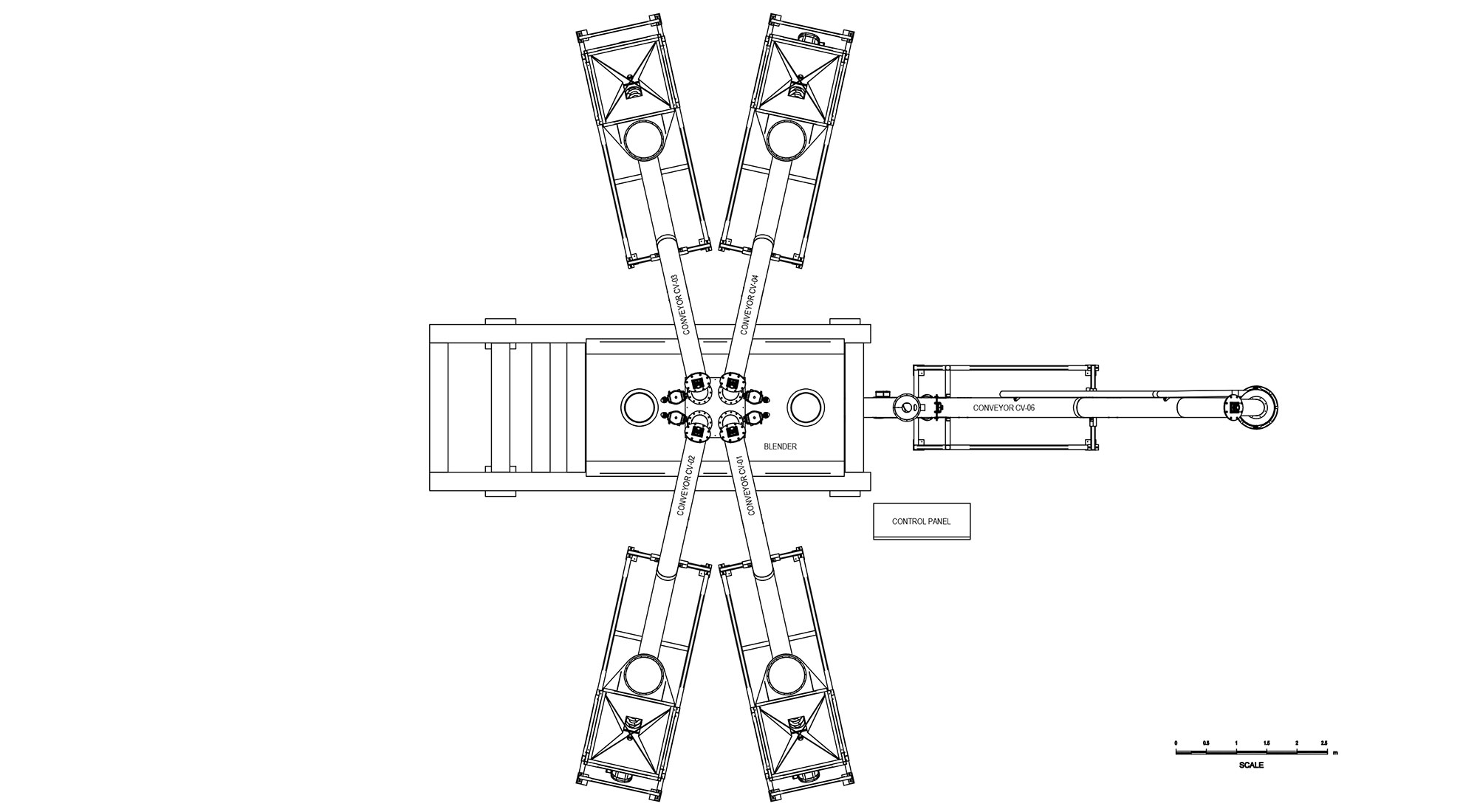

Vortex HD heavy duty ribbon blender is regularly used for mixing cement & sand. Its drive unit including motor, reducer, shaft and rotating agitator is enhanced for cement, using wear resistant steel to extend the agitator’s shelf life.

Vortex also developed PLC controlled auto screw dosing feeding system for blending plant. The Blending Plant for dry powder green cement production is designed to be a fully automatic plant with holds at critical steps in the process requiring operator initiation to proceed. The HMI could store recipes and PLC select certain recipe and control Screw feeders to feed the amount of recipe ingredients. This system greatly facilitate the mixer’s feeding procedure and save labors.