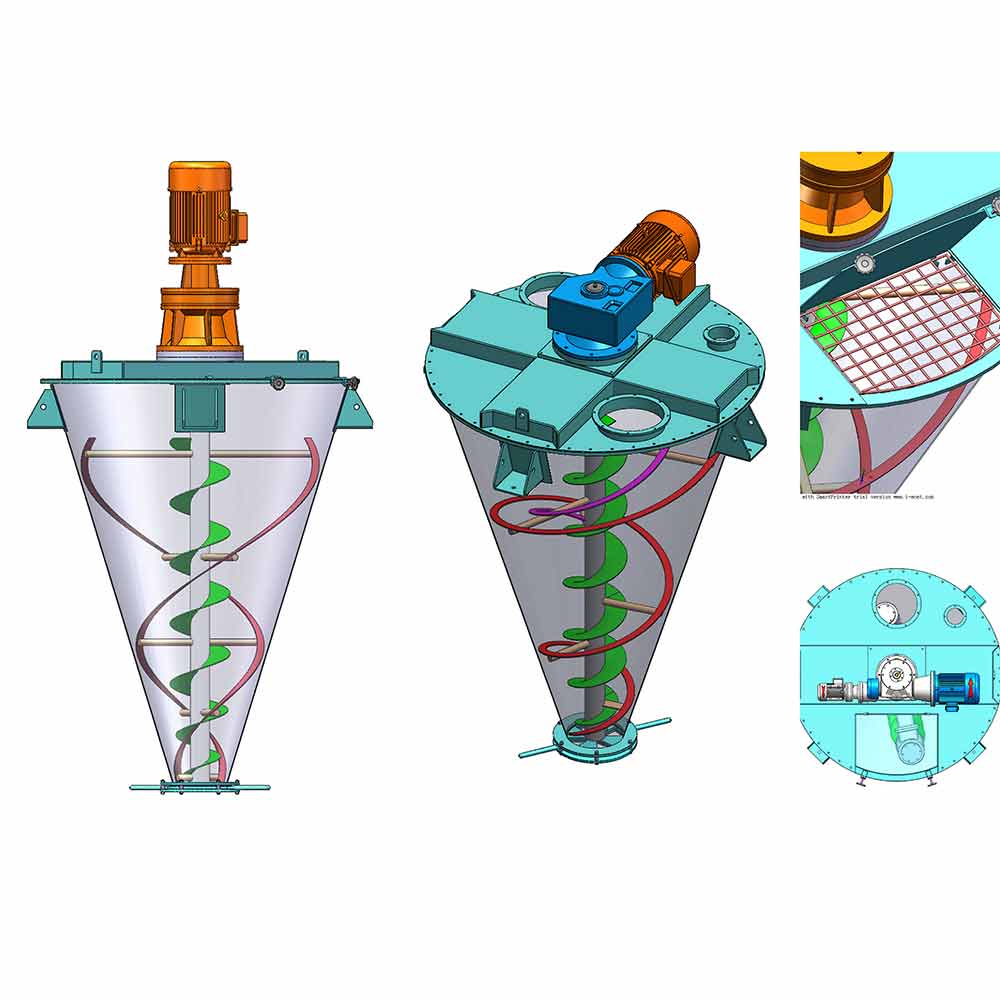

The conical ribbon mixer consists of one ribbon shaft, vertical shape vessel, drive unit, cleanout door and chopper. It is a new developed mixer which is popularly used in food and pharmaceutical industry because of simple structure, easy cleaning and totallly discharging. The ribbon agitator will lift the material from bottom of mixer and fall down by gravity. Furthermore, there is chopper on side of vessel to break agglomerates during mixing. The cleanout door on side will be useful for worker to clean everywhere inside mixer. Due to all drive unit part is designed at outside of mixer, there is no possible of oil leakage into mixer.

Photo Gallery

| Total Volume | 100L – 30000L |

|---|---|

| Construction Material | Carbon Steel, SUS304 Stainless Steel, SUS316 Stainless Steel |

| Discharge Valve | Electric, Manual, Pneumatic |

| Liquid Spray | CIP Clean Nozzle, Liquid Spray Nozzle |

| Jacket | Cool Jacket, Heat Jacket |

| Explosion Proof | Hazardous area zone 20, 21, 22 |

| Anciliary Device | Circular Vibration Sieve, Dump Station, Quantitive Discharge, Screw Conveyor, Storage Tank, Vacuum Conveyor |

Standard Features

- Capacity range from 100-30000L

- Mild Steel/Stainless Steel construction

- Flange Cover or Cone Cover Type

- Multiple Design for Ribbon Agitator

- Normal Temperature and Pressure inside mixer

- Gear Reducer Motor

- Packing Seal

- Chopper for breaking Agglomeration

- Gear Reducer Motor

Special Features

- Vacuum/Pressure inside mixer

- Heating/Cooling Jacket for mixer

- Spraying Nozzle for liquid

- CIP Cleaning System

- Mechanical Seal

- Explosion-proof for electricity

- Electrical Control Panel system

- GMP manufacturing

- Segment Ball Valve

- Other Special Customize Design

Application

- Baby Food

- Instant Food

- Milk Powder

- Essence

- Enzymes

- Flavoring Agents

- Seasoning

- Mineral Substance

- Sugar

- Flour Bakery

- Nutritions

- Bacteria

- Dried Vegetables

- Food Additives

- Herbs

- Pharmaceuticals

- Vitamin Compound

- Cosmetics

Technical Data

| Model | Nominal Volume | Working Volume | Speed (RPM) | Motor Power |

|---|---|---|---|---|

| VRM-0.1 | 100L | 40-60L | 80rpm | 1.5KW |

| VRM-0.3 | 300L | 120-180L | 80rpm | 2.2KW |

| VRM-0.5 | 500L | 200-300L | 80rpm | 4KW |

| VRM-1 | 1000L | 400-600L | 60rpm | 7.5KW |

| VRM-1.5 | 1500L | 600-900L | 60rpm | 11KW |

| VRM-2 | 2000L | 800-1200L | 60rpm | 15KW |

| VRM-3 | 3000L | 1200-1800L | 50rpm | 18.5KW |

| VRM-4 | 4000L | 1600-2400L | 50rpm | 22KW |

| VRM-6 | 6000L | 2400-3600L | 50rpm | 30KW |

| VRM-8 | 8000L | 3200-4800L | 45rpm | 37KW |

| VRM-10 | 10000L | 4000-6000L | 40rpm | 45KW |

| VRM-12 | 12000L | 4800-7200L | 35rpm | 55KW |