Ask An Expert

Frequently Asked Questions

Yes, We can supply simple stand alone panels or automated PLC controlled systems. We normally install and test all controls on our mixers before they are shipped.

Yes, we normally test the mixers before they are shipped and mark out the wire need to connect on the control box.

We manufacture specialty mixing equipment for powder & bulk materials. Included are ribbon blender, plough mixer, conical screw mixer, twin shaft paddle mixer, V blender, double cone blender and other auxiliary equipment such as screw conveyor, quantitive auger filler.

We sell across the world, our cusotmers distribute 5 continents.

Share Us With Your Network

Mastering Industrial Drying with Vortex Mixing Technology: A Comprehensive Guide to High-Performance Dryers

Introduction

Industrial processing organizations heavily depend on drying systems to maintain product quality standards while achieving production operational excellence. During the drying phase of pharmaceutical granules as well as chemical powders and food ingredients it directly controls their quality standards and safety measures and determines their shelf life duration. Vortex Mixing Technology presents industrial drying solutions through its state-of-the-art mixing and drying equipment which operates across multiple applications.

The company produces three dryers through their product range: Mixing Dryer followed by Conical Vacuum Dryer and Fluid Bed Granulator Dryer. These essential devices are built with the dual purpose to deliver exact control systems along with optimal thermal efficiency and considerate product handling capabilities serving industries that demand strict consistency and regulatory compliance.

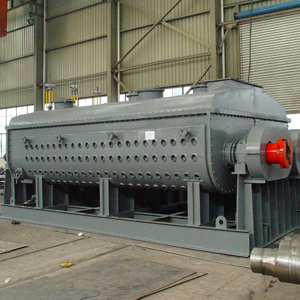

1. Mixing Dryer

Vortex provides the Mixing Dryer as an industrial system which merges mixing operations and drying stages. Each product passing through the horizontal unit experiences complete exposure to heated surfaces because its structure promotes broad material movement.

Key Features of Mixing Dryer:

- The horizontal cylinder design creates the most efficient drying conditions by increasing the amount of material which can come into contact with exposure surfaces.

- The plow-shaped Mixing Tools provide intense homogeneous mixing which breaks up clumps to achieve uniform drying results.

- High-Speed Cutters work as an optional feature to shear and granulate materials during drying operations when size modification is required.

Applications:

The dryer proves most suitable for chemical and food industry products which exist as granules or powders. This equipment successfully dries both sticky materials and heat-sensitive compounds and hygroscopic substances. The device’s strong mixing function enables all particles to receive equal heat contact which produces uniform moisture reduction together with stable particle cohesion.

Benefits:

- Rapid and uniform drying

- High energy efficiency

- Versatile across material types

2. Conical Vacuum Dryer

The Conical Vacuum Dryer functions as an ultimate solution to dry temperature-sensitive products that experience degradation at elevated heat levels. Due to its vacuum system the equipment enables low-temperature evaporation which maintains both chemical structures and material potencies.

Key Features of Conical Vacuum Dryer:

- Vertical Conical Shape: Ensures complete discharge and minimal product loss.

- This unit features a built-in agitator which distributes the product evenly throughout the drying chamber.

- The Solvent Recovery System captures solvent vapors which makes the system efficient for reusing the recovered solvent.

Applications:

The dryer performs exceptionally well for drying wet cakes, slurries or powders in pharmaceutical cosmetic and fine chemical production. This device operates effectively under minimal pressure and temperature conditions thus making it valuable for protecting substances who break down easily due to oxidation or thermal exposure.

Benefits:

- Preserves active ingredients

- GMP-compliant design

- Closed system prevents contamination

Conical Vacuum Dryer

3. Fluid Bed Granulator Dryer

The one-step operation of the Fluid Bed Granulator Dryer enables both granulation and drying processes for continuous production or batch execution. Manufacturers use the Fluid Bed Granulator Dryer as a system which sprays binder onto fluidized powder before it dries the formed granules.

Key Features of Fluid Bed Granulator Dryer:

- The continuous fluidization maintenance through even airflow distribution protects the uniformity of drying and granule formation.

- HEPA Filter System: Ensures a sterile environment, critical in pharmaceutical production.

- Integrated Spray Nozzle: Delivers precise amounts of binder for controlled granulation.

Applications:

The dryer has widespread pharmaceutical applications for controlled-release formulations production as well as instant granule development. The device finds its main application in flavoring powder production and dietary supplement development for the food industry.

Benefits:

- A single compact unit allows both granulation processing and drying operations.

- High-quality granule formation

- Scalable for R&D and production lines

Technological Innovations

Multiple device enhancements within Vortex dryers help users achieve improved control of their processes and enhanced operation experience.

- PLC Controls: The system features PLC controls that enable users to establish detailed drying configuration settings and exhibit real-time processing information.

- Modular Design: Each Vortex unit can adapt through its modular design to suit unique applications so it perfectly integrates with operational manufacturing lines.

- Energy-Efficient Heating Jackets: The application of energy-efficient heating jackets enables users to achieve constant heating profiles while ensuring minimal energy usage.

Industry-Specific Customization

Vortex designs its products to comply with specific needs of each individual industry sector.

- Pharmaceuticals: Compliance with cGMP and FDA standards.

- Food Industry: Use of food-grade materials and hygiene-friendly designs.

- Chemical: The devices demonstrate two main characteristics which involve resistance against corrosion combined with their capacity to process volatile chemical substances.

The adherence of Vortex dryers to strict regulatory standards stems from their design philosophy alignment which ensures both reliable performance and highest level compliance.

Why Choose Vortex Mixing Technology?

- The company Vortex Mixing Technology demonstrates its excellence through its over ten years of operation together with its worldwide client network.

- Each Vortex engineering product receives meticulous manufacture within China’s state-of-the-art assembly areas.

- Through dedicated international logistics teams Vortex provides prompt delivery support along with permanent technical service whenever needed.

- Tarsio implements continuous research and development initiatives to maintain its position at the leading edge of drying technology.

Conclusion

The industrial drying process entails more than just moisture extraction. The final product quality together with its safety and its operational efficiency are completely defined by this pivotal processing phase. Vortex Mixing Technology has expertly designed a comprehensive portfolio of dryers for high-performance mixing and sensitive vacuum applications and advanced fluid bed granulation needs which satisfy modern industrial production requirements.

Through their status as solutions these machines enable manufacturers to earn enhanced outcomes and consistent results in addition to reduced operational expenses. The Vortex dryer selection features models that will fit any food production series or pharmaceutical quality enhancement project requirement.

Ask An Expert