Ask An Expert

Frequently Asked Questions

Yes, We can supply simple stand alone panels or automated PLC controlled systems. We normally install and test all controls on our mixers before they are shipped.

Yes, we normally test the mixers before they are shipped and mark out the wire need to connect on the control box.

We manufacture specialty mixing equipment for powder & bulk materials. Included are ribbon blender, plough mixer, conical screw mixer, twin shaft paddle mixer, V blender, double cone blender and other auxiliary equipment such as screw conveyor, quantitive auger filler.

We sell across the world, our cusotmers distribute 5 continents.

Share Us With Your Network

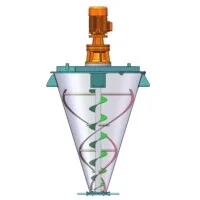

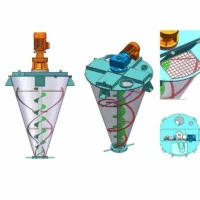

Conical Ribbon Mixer for Precision Blending in Food, Chemical, and Pharmaceutical Industries

Introduction to the Conical Ribbon Mixer

The Conical Ribbon Mixer is specially made for mixing in industrial sites that handle pharmaceuticals, food, chemicals and cosmetics. This mixer was developed using Vortex Mixing Technology and is excellent at mixing dry powders, wet granules and pastes with low or moderate viscosity.

The reason this mixing system is loved is because it soft-handles materials, quickly discharges them and can work in batches. If you have to mix food treatments or pharmaceutical powders, the conical ribbon mixer will help you keep the product’s quality and safety at the required level.

Instructions for the Functioning of a Conical Ribbon Mixer

The reason this mixer works well is because it is based on a straightforward yet valuable principle. The heater contains a straight high vessel with an internal scroll agitator and optional chopper. When the ribbon rotates, it lifts up the materials from the cone’s base and moves them against the side of the vessel. After that, gravity makes the material slowly fall down the center of the cone. Moving the liquid up and down ensures it is always mixed quickly and evenly.

A high-speed chopper is helpful when the product forms lumps and it aids in improving the blend quality. The shape allows the blended materials to be mixed well and ensures that there is no wasted product left in the mixer.

Materials

Premium-grade materials ensure that the Conical Ribbon Mixer stands the test of time, helps keep food products clean and is immune to corrosion. The mixer may be created out of:

- Carbon Steel

- Ultraform 304

- Stainless Steel 316

They are either following or exceeding the standards set by the industry for applications that require good hygiene, resistance to corrosion and strong materials.

Moreover, you can add various features to a mixer to match the requirements of different processing jobs.

The discharge valve may be manual, pneumatic or electric.

- Jackets can be installed for applications requiring heating or cooling

Some tanks come with special liquid spray nozzles to enable ejecting liquids in fine amounts.

- Functioning through Vacuum or Pressure

Explosion-proof designs are made for ATEX Zone 20, Zone 21 and Zone 22.

The pharmaceutical equipment is designed to comply with guidelines of GMP and FDA.

Custom settings ensure that manufacturers can adjust their machines to adhere to the exact rules in their industry.

What Makes Learning Teamworks Unique

Conical Ribbon Mixers have design features that ensure better and faster production. Let’s highlight some of the main advantages below.

1. Uniform Distribution of Substances

The special ribbon agitator helps the mixer blend items with different composition, regardless of the different densities and sizes of the components. Thanks to this process, the final outcome is always of high quality.

2. Soft mixing movement

Unlike high-shear mixers, the Conical Ribbon Mixer carefully mixes delicate substances. Because of this, the manufacturing of products in food and pharmaceutical industries requires extra attention to ingredient integrity.

3. Easy emptying and efficiently making use of all of the mix

Since the mixer is cone-shaped, almost all the mixed material comes out of it. It allows you to prevent wasting products and also to make production changes more quickly.

4. Smart and Uncomplicated

The mixer can be cleaned quickly and well. A CIP nozzle, as well as other design features, make this machine perfect for industries that require strict hygiene measures.

5. There is no chance of oil running into the fuel tank.

An external drive system is used in the mixer to guarantee that no oil will go into the mixing chamber. As a result, the environment stays uncontaminated and clean.

6. Energy Efficient

Efficient mixing and energy saving are made possible thanks to the agitator design used in the bowl mixer.

Industry Applications

This mixer can be used for various tasks and purposes due to its versatility.

Food Industry

Certain dishes require the inclusion of instant dry soup mixes.

- Seasonings

- Instant food powders are available on the market.

- Dairy powders and combinations

- Nutrition or vitamin types

Pharmaceutical Industry

There are medicines that exist in powder form.

- Herbs that have undergone extraction

- Products with a combination of enzymes and vitamins

- Nutraceutical powders are one kind of nutraceutical

Chemical Industry

- Cosmetic powders are made from all kinds of minerals

- Pigments and colorants

- Additives

- Polymers and resins are well-known substances in chemistry.

It is essential for production in batches because it can mix, coat, granulate and carry out blending, whether wet or dry.

Optional extras and tools for easier work.

If integrated with automation and additional machines, the Conical Ribbon Mixer becomes more efficient and reduces worker expenses, for instance:

- Systems relying on vacuum to move materials

- Screw types

- Tanks made of steel

- Batching machines

- Rotary screens

- Panels using programmable logic control (PLC)

Using these features allows you to work more efficiently, get reliable results and increase productivity.

Routine Maintenance

Caring for your Honda Conserva regularly is an easy task. Thanks to its sturdy design, hard-wearing pieces and parts that are easy to get to, this machine will last a long time and experience small intervals of downtime. Vortex Mixing Technology ensures your equipment runs smoothly by providing you with adequate technical assistance, extra parts and training.

Conclusion

Manufacturers can achieve precise, clean and power-saving mixing with the Conical Ribbon Mixer from Vortex Mixing Technology. Due to its unique structure, high-quality materials and many custom possibilities, this type of building is useful in many fields.

In the food, pharmaceutical or chemical industry, the mixer can make your work easier and give you more control over the product.

Ask An Expert