Ask An Expert

Frequently Asked Questions

Yes, We can supply simple stand alone panels or automated PLC controlled systems. We normally install and test all controls on our mixers before they are shipped.

Yes, we normally test the mixers before they are shipped and mark out the wire need to connect on the control box.

We manufacture specialty mixing equipment for powder & bulk materials. Included are ribbon blender, plough mixer, conical screw mixer, twin shaft paddle mixer, V blender, double cone blender and other auxiliary equipment such as screw conveyor, quantitive auger filler.

We sell across the world, our cusotmers distribute 5 continents.

Share Us With Your Network

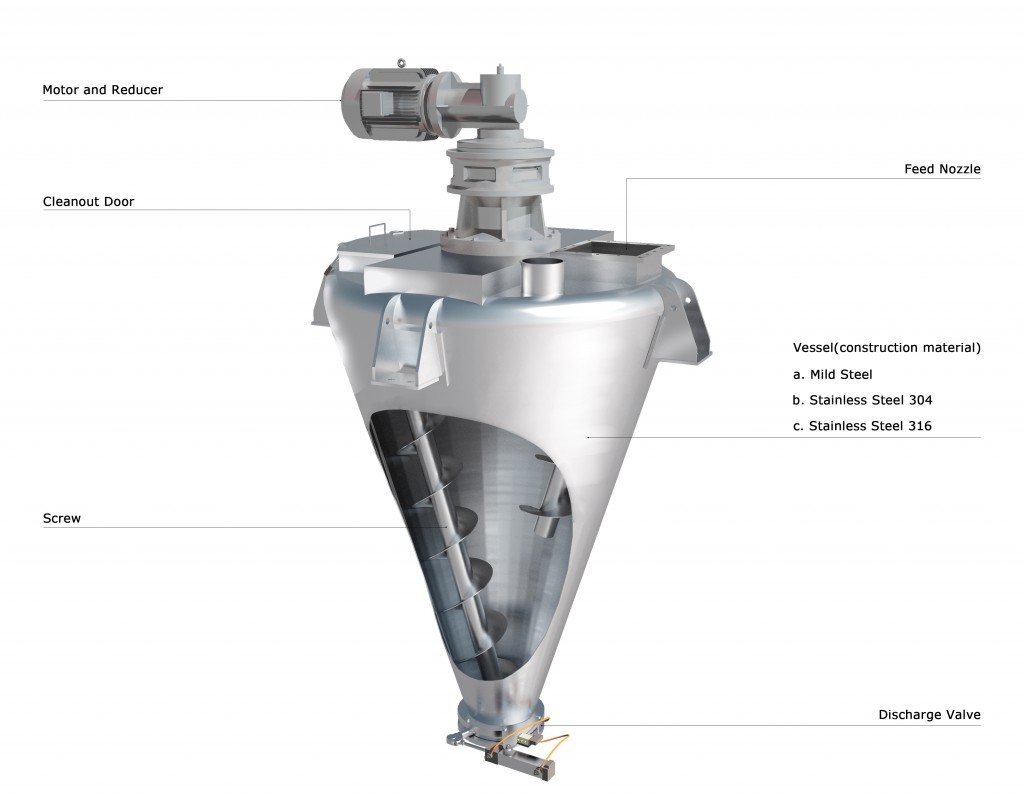

Conical Screw Mixers

Conical Screw Mixers (also called Nauta Mixers) make use of a conical chamber with a vertical screw that mixes the powder or substance.

Working principle

First step is charging of mixer from the top, manually or vide pneumatic or mechanical conveying. After the mixer is charged the mixing process starts.

The mixing is carried by means of 3 distinct intermixing actions:

The screw agitator, turning on its axis, produces a lifting action as it spirals the materials in an upward flow.

At the same time, orbiting the tank, the screw removes material away from the wall and deflects it into the centre of the tank.

Material lifted by the screw gravitates downward, thoroughly intermixing with material being spiraled upwards.

The typical speed of the central screw is 70 to 80 Rpm. The Tip speed can fluctuate from 1 to 3 m/s. The result is most intimate intermingling of all ingredients. The mixing time is depending on product characteristics, mixing accuracy and batch size.

Ask An Expert