Ask An Expert

Frequently Asked Questions

Yes, We can supply simple stand alone panels or automated PLC controlled systems. We normally install and test all controls on our mixers before they are shipped.

Yes, we normally test the mixers before they are shipped and mark out the wire need to connect on the control box.

We manufacture specialty mixing equipment for powder & bulk materials. Included are ribbon blender, plough mixer, conical screw mixer, twin shaft paddle mixer, V blender, double cone blender and other auxiliary equipment such as screw conveyor, quantitive auger filler.

We sell across the world, our cusotmers distribute 5 continents.

Share Us With Your Network

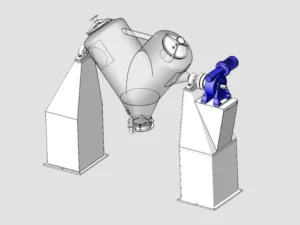

V Type Blender: Gentle and Uniform Powder Mixing for Precision Applications

V Type Blender: Gentle and Uniform Powder Mixing for Precision Applications

As a reliable and effective solution for the dry powder and granular mixing within industries where precision and hygiene of products are not negotiable the V Type blender occupies the leading position. Designed by Vortex Mixing Technology, this blender is designed specifically for the best performance on the applications where shear-sensitive materials require even mixing without jeopardizing their structure.

The V Type Blender is suitable for pharmaceutical, food, chemical and cosmetic industries, and this machine strikes an elegant balance between simplicity and minimum energy requirements and consistently produces mixing results. Whether it is making mess blends of active ingredients in medications or mixing seasoning blends for food production, the V Blender provides a proper and contamination-free mixture.

V Type Blender – What Is It?

The V Type Blender, also referred to as a V Cone Blender, consists of two hollow cylindrical shells joined at an angle to form a “V” shape. Inside, materials are tumbled and interfolded as the vessel rotates thus helping random distribution of particles. The shape allows for an efficient mixing pattern which eliminates the dead zones and guarantees that there is no difference in the blending of dry materials

As the V Blender claymills gently tumbles the dry feed as opposed to subjecting it to mechanical agitation, this type of mixer is excellent for working with fragile and friable materials that degrade easily in more aggressive mixing devices.

Vortex V Type Blender’s Unique Points

Vortex Mixing Technology has designed the V Type Blender with high performance in mind, ease of cleaning, and total customizability to cater for various industry needs. Some standout features include:

- Symmetrical V-Shaped Chambers: Engineered to ensure that there is uniform movement and combination of materials with less energy operation.

- Low Shear Mixing: It is appropriate for delicate materials that are to be manipulated in a delicate manner.

- Multiple Discharge Options: Butterfly valve/or slide gate to discharge products completely without residue.

- Optional Intensifier Bar: Supporting deagglomeration or mixing of small amounts of liquid additives.

- GMP and FDA Compliance: Conforms to sanitary and safety standards of production of pharmaceuticals and food products

- Customizable Construction: Made of carbon steel, stainless steel 304 or 316L for corrosion resistance and purity of product.

- Capacity Range: Depending on the production requirement, from 100 liters to 20,000 liters.

Applications

The ease of use and efficiency of the V Blender puts it as an ideal solution to many industries which need dry powder mixing. This is the way various sectors benefit from this equipment:

1. Pharmaceutical Industry

The V Blender is highly important for the pharmaceutical industry in the mixing of fine powders, active ingredients, and excipients. The gentle tumbling action preserves the integrity of delicate particles, while this application would be important for dosage uniformity and product consistency.

V blenders tend to be commonly used in tablet and capsule formulation where small differences in the distribution of ingredients may render products ineffective. An optional intensifier bar provides the manufacturers with the ability to add binders or break down small chunks without adding heavy shear.

2. Food Industry

The V Blender is ideal for food manufacturing with regard to manufacture of seasoning blends, baking powders, dehydrated soups and beverage mixes. Its hygienic design, ease of cleaning, and stainless steel construction put it in a position to be in direct contact with food-grade materials.

Its capability of blending without overheating ingredients keeps taste, color, and nutritive values thus important in food processing.

3. Chemical Industry

V Type Blender is a type of blender that is popular for use in fine chemical powders like pigments, resin, polymers, and fertilizers. Its closed system prohibits dust emissions and guarantees the safety of the operator who works with volatile or hazardous substances.

Chemical producers recognize the rehearsal nature, scale-up attention, and explosion-proof approach of the V Blender.

4. Cosmetic and Personal Care Industry

Cosmetic powders and beauty product bases need a homogenous blend of components such as talc, pigments, scent and so forth. The soft activity of the V BLENDER avoids color fade out or even separation of ingredients, and thus produces a distinctive product with proper visual and performance qualities.

It has stainless steel finish that makes it provide a clean sterile mixing room which is essential for personal care products formulation.

V Type Blender Benefits

The V Blender is highly renowned for its performance benefits and particularly when it comes to precision-oriented applications. Some of its biggest advantages are:

1. Uniform Mixing

Through rotation of the V-shaped shell, the blender is able to ensure that powders are divided and re-combined repeatedly. This movement enables a homogenous mix; without dead zones and particle segregation.

2. Gentle Handling

Minimal shear reasons makes the V Blender perfect for soft as well as flowing materials. It minimizes dust formation and also enhances particle form that is important in pharmaceutical and food products.

3. Easy Discharge and Cleaning

From its configuration, the V Blender allows near-total emptying of materials hence reduction of wastes. Its smooth inner surfaces and accessible openings also make cleaning process and product changeovers easy.

4. Energy Efficient

The power consumption of blender is reduced since it uses gravity and vessel rotation to operate rather than the high speed agitation hence reducing the expense.

5. Scalable and Customizable

Vortex has various sizes and configurations from the pilot batches in the labs to full scale. Custom features that could be requested include automatic loading systems and PLC controls, as well as CIP (clean-in-place) systems.

Maintenance and Operational Tips

To ensure perfect running and maximum life of your V Blender, do some of the following recommended maintenance practices:

- Routine Inspection: Lookout for wear of seals bearing and revolving parts.

- Lubrication: Ensure that the gearbox components, as well as the shafts, are properly lubricated.

- Cleaning Protocols: Rinse between batches, in particular when changing products, in order to avoid cross-contamination.

- Calibration and Control Checks: Regularly test sensors, timers, and PLC for the purposes of upholding blending accuracy.

- Training: Make sure that operators have safe loading, unloading, and startup procedures.

Why Choose Vortex Mixing Technology

Vortex Mixing Technology is one of the reputable manufacturers of high-performance mixing equipment. With a rich experience in the industry and holding focus on innovation; the company provides credible and customizable solutions for industrial mixing problems.

Some of the most effective benefits of preferring Vortex are:

- Precision-engineered blenders

- Overseas compliance to CE, GMP and FDA standards

- Rapid delivery and installation support

- Competitive pricing and after-sales service

- Ability to custom design for complex needs.

Be it in the production of new pharmaceutical products or in enhancing the production of food, Vortex’s V type blender provides quality and flexibility to keep up with the industry standards.

Conclusion

V Type Blender of Vortex Mixing Technology is the solution that can withstand the strains of industries that crave precision, hygiene, and gentle handling of dry powders and granules. Low-shear mixing, customizable components, and compliance with GMP and FDA standards make it ideal for the use in pharmaceutical, food, chemical, and cosmetic processing.

Whether for sensitive formulations or high volumes, the V Blender delivers the same high performance, ease of cleaning, and cost savings for energy consumption − choosing which means easy choices for manufacturers who pursue quality and operational excellence.

Ask An Expert