Ask An Expert

Frequently Asked Questions

Yes, We can supply simple stand alone panels or automated PLC controlled systems. We normally install and test all controls on our mixers before they are shipped.

Yes, we normally test the mixers before they are shipped and mark out the wire need to connect on the control box.

We manufacture specialty mixing equipment for powder & bulk materials. Included are ribbon blender, plough mixer, conical screw mixer, twin shaft paddle mixer, V blender, double cone blender and other auxiliary equipment such as screw conveyor, quantitive auger filler.

We sell across the world, our cusotmers distribute 5 continents.

Share Us With Your Network

Optimizing Animal Feed Production with Vortex Mixing Machines A Guide to Efficient and Consistent Feed Blending

Animal feed manufacturing stands as a necessary step in agricultural and food production since all livestock poultry and aquaculture and pet industries need premium quality feed for maintaining healthy development, strong immune system and peak productivity levels. The mixing process remains a vital component which unifies multiple ingredients into a standardized nutritional blend.

Vortex mixing machines are designed to meet the demands of modern animal feed production facilities Whether operating on a small scale or running an industrial mixing line Vortex offers high capacity mixers that deliver consistency hygiene and efficiency

Vortex mixing solutions from the company enhance feed quality and nutritional precision while decreasing manufacturing time throughout the animal feed production process.

Why Mixing Matters in Animal Feed Production

The distribution of vitamins minerals proteins grains and other nutritional components throughout every production batch of feed ranks as the most crucial animal feed manufacturing step

- Unmixed feeds within a batch lead to multiple problems.

- Inconsistent nutritional intake for animals

- Growth delays and health issues

- Wasted raw materials and additives

- Reduced product performance and market trust

Feed mixing ensures that all nutrient proportions remain precise in each quantity of feed for achieving optimum animal health and efficient feed utilization

Challenges in Feed Mixing Without the Right Equipment

Traditional mixing techniques face multiple operational problems when used for feed production.

- Segregation of ingredients becomes a problem during storage or transport operations.

- Uneven distribution of micro and macro components

- Long mixing times that slow down production

- Cross contamination between feed types

- Material and dust losses occur while mixed feed products complete the process.

Vortex mixing machines solve these issues with precision engineering material-safe construction and smart control systems that enhance mixing outcomes

Vortex Mixing Machines Built for the Animal Feed Industry

Vortex offers feed processing-specific industrial mixing machines which succeed in dry powder blending, granular mixing and semi-moist compound operation.

Three types of Vortex mixers designed for feed manufacturing include

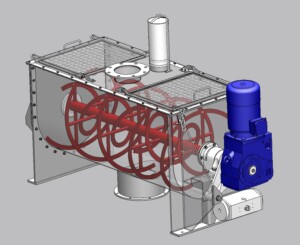

1 Horizontal Ribbon Mixers

The double helix ribbon blade ambits the ingredients toward the center while extending them outward which results in complete mixing of powder and granular feed formulations.

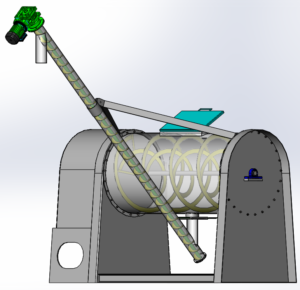

2 Paddle Mixers

The U-shaped trough of paddle mixers receives rotating multi angled paddles which create gentle and efficient mixing capability for delicate substance combinations.

3 Batch Mixers

Users can operate Vortex batch mixers for specific recipe mixing while maintaining total control over time speed and ingredient inputs when processing small to medium batch dimensions.

4 Continuous Mixers

The mixing process of vortex continuous mixers delivers continuous ingredient blending during chamber operations which produces volume gains and quickens overall handling duration.

Stainless steel components and flexible speed controls together with user-friendly discharging systems make their machines efficient for clean processing needs.

The Vortex Animal Feed Mixers Offer Four Main Features

High Mixing Uniformity

A Vortex mixing system provides complete ingredient homogeneity for both small fine particles and large grain materials which results in optimal feed quality performance.

Fast Mixing Times

The combination of efficient motors and perfect blade configuration enables Vortex mixers to cut blending periods which boosts facility production and decreases cycle durations.

Dust Control and Safety

The enclosed mixing chamber protects workers from dust exposure and decreases raw material waste because of its design.

Easy Cleaning and Maintenance

Electronic cleaning and maintenance processes become easier because the machine features smooth internal surfaces and quick-access points and tool-less disassembly stops product transfer between different feed types

Customizable Batch Sizes

The Vortex product range includes micro-batch mixers capable of processing 100 kilogram batches yet offer continuous multi-ton capacity which scales according to your facility needs and product range.

Control Panel Integration

The equipment has friendly operator interfaces for setting mixing times and speeds and operational sequences and automated functions through programmable logic controllers.

Applications of Vortex Mixing Machines in Animal Feed Lines

Poultry Feed Production

Vortex mixers merge corn soybeans amino acids with micronutrients into homogenized poultry feed producing nutrition that enables healthy chicken development and egg quality

Cattle and Livestock Feed

A uniform mixture of grain silage minerals alongside supplements creates the necessary nutrition for cows, goats and sheep to enhance their digestion processes while improving milk production alongside meat development.

Aquaculture Feed

The formulation process of fish and shrimp feed requires high protein blends and binders which Vortex mixers efficiently maintain both the pellet quality and nutrition quality throughout the process.

Pet Food Blending

The use of vortex mixers extends to dry pet food production since they achieve optimal flavor distribution and maintain risk-free ingredient handling.

Premix and Additive Integration

Vortex mixers serve both complete feed blending purposes while they blend premix formulations of vitamins and trace elements with carrier components before further use.

Benefits of Using Vortex Mixing Machines for Animal Feed

Improved Feed Quality

Better performance in the field is achieved through enhanced mixing because animals get consistent nutrition that results in improved health with faster growth and higher production rates.

Operational Efficiency

The efficiency of Vortex mixers includes quick batch runs combined with automatic maintenance features that result in reduced expenses for feed processing factories and their contract customers.

Lower Feed Wastage

The exact mixing technique stops ingredients from separating and creating abnormal weight distribution leading to less product loss with every batch

Compliance with Safety Standards

Vortex machines implement stainless steel components to fulfill feed safety requirements and quality control specifications through traceable process controls.

Adaptability for Multiple Recipes

A single mixer provides quick and simple format transitions so it can work across different product ranges without productivity interruption.

Real World Use Case A Livestock Feed Mill Doubles Output with Vortex Mixers

By switching to a Vortex horizontal ribbon mixer this feed manufacturer achieved under 10-minute mixing time instead of their original period of 25 minutes which led to improved product consistency without the need for reprocessing.

The facility managed to increase daily production levels by 100% and cut workforce requirements down by 30% and still delivered high-quality products alongside better client satisfaction.

How to Choose the Right Vortex Mixing Machine for Your Feed Line

The selection of a Vortex mixer for animal feed requires several factors to be taken into account.

Type of Ingredients

Every material used in the mixture including grains powders and oils or binders determines the suitable blade type and blending process duration.

Production Volume

Determine your daily tonnage production to pick between batch or continuous mixer systems.

Mixing Time Goals

Select a mixing device consisting of specifications that match your operational speed requirements along with broader production speed expectations.

Cleaning Frequency

Fast cleanout features with easy access options should be selected by operations that frequently need to switch between feed species and types.

Integration Needs

You should evaluate whether your mixer must integrate with feeding hoppers and conveyors as well as bagging machines and weighing systems.

Maintenance and Support from Vortex

Vortex mixing machines are designed for long term use with minimal maintenance needs Every unit comes with

- A maintenance guide for routine inspection

- Access to OEM replacement parts

- Remote troubleshooting support

- Installation assistance and operator training

- The company offers service plans for big operation facilities

The feed production line keeps running smoothly with extended equipment life due to this maintenance approach

Conclusion: Elevate Feed Production with Vortex Precision Mixing Solutions

Animal feed manufacturers who seek success must achieve operational consistency and efficiency because the appropriate mixer will revamp your entire production while minimizing processing time while improving both product standards and financial profits.

Vortex mixing machines are built for the demands of modern feed production With durable stainless steel construction precise blending action and user friendly controls Vortex helps you deliver consistent high performance feed with every batch

Any operation that produces feed for poultry livestock aquaculture or pets can depend on Vortex mixing machines to deliver industrial reliability together with technical excellence for their mixing process.

Ask An Expert