Ask An Expert

Frequently Asked Questions

Yes, We can supply simple stand alone panels or automated PLC controlled systems. We normally install and test all controls on our mixers before they are shipped.

Yes, we normally test the mixers before they are shipped and mark out the wire need to connect on the control box.

We manufacture specialty mixing equipment for powder & bulk materials. Included are ribbon blender, plough mixer, conical screw mixer, twin shaft paddle mixer, V blender, double cone blender and other auxiliary equipment such as screw conveyor, quantitive auger filler.

We sell across the world, our cusotmers distribute 5 continents.

Share Us With Your Network

How to Prevent Agglomeration during Mixing

During Mixing the topic of agglomeration comes up, it’s natural to think first of the unit operation of size enlargement— causing particles to adhere to each other — and the benefits this process provides for many dry bulk products. Yet agglomeration isn’t always a positive thing. Unwanted agglomeration is a natural phenomenon that can occur under certain conditions during mixing operations, causing a host of problems. This article looks at the sources of unwanted agglomeration in mixing operations and describes ways to prevent it.

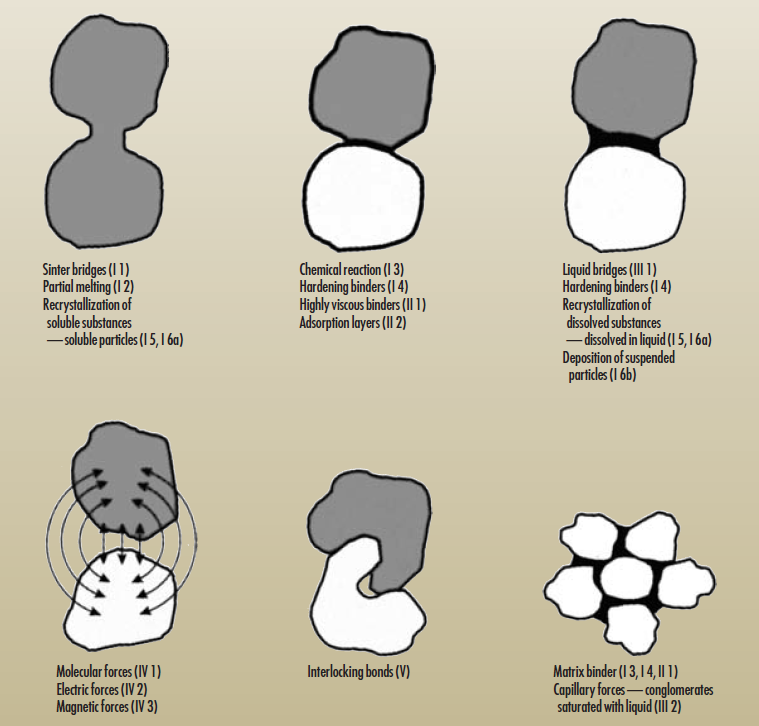

When mixing dry or moist materials via ribbon blender, plough mixer or other mixing machine, the finest ingredients in the mixture can form unwanted agglomerates. Such agglomerates are held together by molecular forces (in which the molecules in one particle interact with the molecules in another, bonding them together), electrostatic forces (one of the electrical forces, in which particles contact each other, tools, or walls and create electrostatic forces, whereafter oppositely charged surfaces attract each other and form bonds), and capillary forces (in which liquid bridges develop between the particles and bond them together). To prevent or break up the agglomerates, select a mixer that can generate enough motion of the mixture’s bulk mass to produce shear or frictional stresses, or equip the mixer with special disintegration devices, such as knife heads and choppers, and apply these stresses to the agglomerates. Unwanted agglomeration can also occur when you stir solids into a liquid to produce a suspension or dispersion. If the solid particles have a strong agglomerating tendency, you can prevent agglomerates from forming by adding a dispersion agent, such as a detergent surfactant, to the mixture. Creating shear forces in the liquid will also destroy agglomerates, so another way to break up unwanted agglomerates is to select an agitator that can generate the highest possible shear gradient during mixing.

Ask An Expert