Ask An Expert

Frequently Asked Questions

Yes, We can supply simple stand alone panels or automated PLC controlled systems. We normally install and test all controls on our mixers before they are shipped.

Yes, we normally test the mixers before they are shipped and mark out the wire need to connect on the control box.

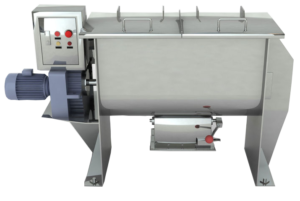

We manufacture specialty mixing equipment for powder & bulk materials. Included are ribbon blender, plough mixer, conical screw mixer, twin shaft paddle mixer, V blender, double cone blender and other auxiliary equipment such as screw conveyor, quantitive auger filler.

We sell across the world, our cusotmers distribute 5 continents.

Share Us With Your Network

Advanced Packaging Machines by Vortex Enhancing Speed Precision and Productivity in Modern Manufacturing

As industries continue to evolve the demand for smart reliable and high speed packaging solutions is more important than ever Manufacturing companies across sectors are seeking automation technologies that streamline operations improve packaging quality and keep up with fast paced production schedules

Vortex responds to this demand with a complete line of advanced packaging machines designed for efficiency precision and adaptability From form fill seal machines to automatic labeling systems Vortex packaging equipment is built to handle everything from small batch operations to full scale industrial packaging environments

In this comprehensive guide we explore the types of packaging machines offered by Vortex their benefits for different industries and why choosing the right equipment can revolutionize your packaging process

The Growing Importance of Automated Packaging

Packaging serves as one of the essential manufacturing operations since it protects products and communicates brands while meeting standards along with enabling longer shelf life. Therefore automated packaging has become essential for large-scale operations because manual labor proves unsustainable due to numerous factors.

Automation through packaging machines improves

- Packing speed and throughput

- Accuracy and material efficiency

- Labor savings and cost reduction

- Product safety and hygiene

- A consistent quality standard of packages together with uniform branding schemata

Vortex provides high-end systems that require minimal operator involvement to perform their functions.

Vortex Packaging Equipment Overview

Vortex offers a wide range of packaging machines each tailored to specific tasks within the production process Key categories include

1 Vertical Form Fill Seal Machines VFFS

VFFS machines serve the food and chemical industries by creating pouches from flat film while filling product then automatically sealing the package in a single continuous operation to pack powders, granules, liquids and solids.

2 Pouch Packaging Machines

Vortex pouch fillers produce clean flexible handling of products while providing efficient operation for applications that span coffee snacks and pet food pharmaceutical packaging and zip lock methods of packaging.

3 Flow Wrapping Machines

Flow wrappers complete horizontal seals along products to deliver clean compact packaging solutions for cosmetics and medical supplies and bakery tools and similar products which remain fresh and attractive inside the packaging system.

4 Labeling Machines

Labeling machines utilize automation to apply labels onto bottles along with jars and boxes and bags while maintaining perfect alignment and distinct prints INC This automation enhances product appearance as well as tracking capabilities.

5 Cartoning and Box Packaging Machines

Cartoning and box packaging machines perform automated blending of folding operations and gluing while filling tasks which enables fast precise secondary packaging of consumer goods and pharmaceutical products.

6 Capping and Filling Machines

The filling and capping machinery provided by Vortex properly measures liquid and powder amounts while delivering dependable closing systems which simultaneously achieve efficient production speed while preventing leaks.

These machines operate independently along with the ability to merge into complete packaging assembly lines which maximize operational effectiveness.

Industries Served by Vortex Packaging Equipment

Food and Beverage Industry

Packaging machines play a vital role in preserving freshness preventing contamination and presenting food products attractively Vortex supports food producers with equipment for bagged snacks bottled sauces powdered supplements and vacuum sealed items

Pharmaceutical and Nutraceutical Industry

Precision and hygiene are paramount when packaging capsules powders and liquids Vortex’s pharma grade packaging machines offer dust free filling accurate dosage control and tamper proof sealing for compliance and safety

Cosmetics and Personal Care

Vortex solutions utilize tubes bottles and pouches to deliver precise and flawless packaging and labeling of creams oils and powders which results in improved brand reputation through high-end presentation

Chemical and Industrial Goods

Vortex develops tough packaging solutions that use anti corrosive components and implement contamination control systems to handle detergent products pesticides lubricants as well as adhesives

Consumer Packaged Goods CPG

Vortex develops retail packaging solutions which ensure safe wrapping, appropriate boxing and sufficient labeling for toy distribution as well as electronics hardware and stationery products for effective display.

The Main Characteristics of Vortex Packaging Solutions

Modular Design

Vortex systems have modular build structures which enable organizations to expand their functional capabilities such as filling and sealing and labeling as needs change.

Stainless Steel Construction

The sanitary operation of equipment streamlines under corrosion resistant framing conditions especially in food processing facilities and pharmaceutical operations.

Touchscreen Control Panels

The machine operation becomes simpler through user-friendly HMI interfaces which also allow users to manage recipes and solve technical problems.

Servo Driven Motors

By achieving precise speed and motion control the packaging operation becomes more accurate which results in less product waste.

Tool Free Changeovers

The quick format switching option between products shortens downtime periods while making machines more flexible.

Smart Sensors and Automation

Automatic weight monitoring and photoelectric sensors function together to guarantee product uniformity while removing defective packages completely using automated detection.

Benefits of Using Vortex Packaging Equipment

Increased Output

Automated systems outperform manual labor to deliver shorter processing times which prevents system backlog and fulfills high volume order requests

Reduced Human Error

The combination of precision engineering with programmed automation eliminates all potential errors which occur when measuring or when applying seals and labels.

Better ROI

Long term financial savings acquired through continuous production efficiency and minimized material losses enable quicker returns from investment capital.

Improved Product Protection

Product preservation happens through careful package sealing which extends shelf time thus generating customer contentment during transportation and storage periods.

Regulatory Compliance

Vortex engineers its machinery to fulfill food safety GMP requirements as well as industry certification needs

Customization and Integration with Production Lines

Vortex follows an approach that acknowledges the individuality of every production setting The company provides

- Machine customization for size speed or materials

- Integration with conveyors coders and inspection units

- Technical support for setup and operator training

- Engineering support for layout and efficiency improvement

The company supports clients through various stages of packaging line automation starting from manual to semi automated and reaching full automation depending on their volume requirements and financial capability

Sustainability in Packaging with Vortex

Sustainable packaging goals can be achieved by modern manufacturing companies through Vortex solutions which help them pursue these targets.

- Manufacturing equipment exists to handle both compostable and recyclable packaging materials in film form.

- The machines feature precise filling capabilities to stop material waste through excessive additions.

- Our company has developed eco-friendly sealing systems which operate using diminished amounts of energy.

- Flexible machines for thinner lighter packaging options

These workflow solutions enable the decrease of your environmental impacts while ensuring operational excellence.

Real World Example A Food Brand Boosts Output with Vortex

After switching to an Vortex vertical form fill seal unit from manual bag sealing the snack food producer experienced a 40 percent decrease in labor hours while their packaging speed increased by 60 percent and they cut material waste by 25 percent during their first three months.

Vortex equipment provides tangible benefits for all production line operations

Maintenance and After Sales Support

Vortex packaging machines are designed for longevity with minimal maintenance All clients receive

- The equipment includes complete user instructions together with detailed maintenance plan documentation

- Access to spare parts

- Technical assistance from experienced engineers

- Remote diagnostics for troubleshooting

The company dedicates itself to keeping your packaging line operational and free from interruptions.

Conclusion: Power Your Production with Smart Packaging from Vortex

Vortex delivers comprehensive packaging solutions which include liquid sealing and powder filling combined with box labeling and pouch packaging to modern manufacturing facilities through equipment designed for productivity enhancement and quality improvements and cost reduction in multiple industries.

Due to its modern technology together with instinctive control panels and versatile capabilities Vortex packaging solutions function perfectly as a business expansion partner that gives you both certainty and sustainable growth

Explore our full catalog of packaging machines today and speak with a product expert to find the solution that fits your production line and packaging goals

Ask An Expert