Ask An Expert

Frequently Asked Questions

Yes, We can supply simple stand alone panels or automated PLC controlled systems. We normally install and test all controls on our mixers before they are shipped.

Yes, we normally test the mixers before they are shipped and mark out the wire need to connect on the control box.

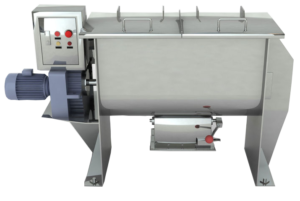

We manufacture specialty mixing equipment for powder & bulk materials. Included are ribbon blender, plough mixer, conical screw mixer, twin shaft paddle mixer, V blender, double cone blender and other auxiliary equipment such as screw conveyor, quantitive auger filler.

We sell across the world, our cusotmers distribute 5 continents.

Share Us With Your Network

The Ultimate Guide to V-Type Blenders for Industrial Powder and Granule Mixing

Introduction to V-Type Blenders

Quality dry product manufacturing and efficient production processes depend on a complete and repeated mixture of raw materials. Of all industrial mixers on the market today the V-Type blender shines as one reliable tool to blend powders and granular materials completely.

These twin-shell blenders hold the name V-cone mixers because their design takes the shape of a V. Originally developed for pharmaceutical applications, V-Type blenders are now widely used across food processing, chemical production, and other industries requiring precise dry material blending.

This comprehensive guide will examine how V-Type blenders work, their key advantages, typical applications, and important considerations for selecting and maintaining these industrial mixing machines.

How V-Type Blenders Work

The operation principle of V-Type blenders is both simple and ingenious. The machine is made up of two cylindrical steel tubes welded at a 90-degree angle for a V-shaped formation. The special V design arrangement builds an efficient blending area because of these functional modes:

After loading dry materials enter the blender shells at the charging ports. Paced from 10 to 25 rotations per minute the machine splits and unites material as it operates.

During rotation cycles the powder or granules divide as they go up the sloped V surfaces before merging as they flow inside toward the peak. Continuous breaking and rejoining of materials inside the unit forms a blended mix without using mechanical agitators or parts that could damage sensitive substances.

Most V-Type blenders include intensifier bars or baffles mounted along the interior length of the shells. The system parts detach material clusters and strengthen the blending process especially with powders that stick together easily.

Product discharge happens through the bottom opening of the V-shape unit to empty all contents without leaving material traces behind. Most V-Shaped blenders use butterfly or slide valve systems that let users control the discharge flow into processing tools or containers.

Key Advantages of V-Type Blenders

V-Type blenders offer several significant benefits that make them preferred choices for many industrial mixing applications:

Superior Mixing Uniformity

The combination of V-shaped design and rotating movement enables smooth consistent mixing that does not vary product composition. Manufacturing pharmaceutical products requires perfect blending which this mixer achieves very well.

Gentle Material Handling

Unlike high-shear mixers that can damage fragile particles, V-Type blenders provide gentle tumbling action that preserves material integrity while still achieving through blending. The machines handle sensitive materials such as instant drink powders and vitamin compounds without damaging them.

Easy Cleaning and Maintenance

With no complex internal mechanisms and smooth stainless steel surfaces, V-Type blenders are relatively simple to clean and maintain. Most models include fast-release clamps and sanitary elements that meet food and medicine industry product quality standards.

Versatile Capacity Options

Manufacturers offer V-Type blenders in a wide range of sizes, from small laboratory-scale units handling a few liters to large industrial models with capacities exceeding 10,000 liters. These machines work at both start-up research and operational manufacturing levels.

Energy Efficiency

Compared to other industrial mixers, V-Type blenders typically require less power to operate since they rely primarily on gravity and vessel rotation rather than mechanical agitation. Using this technique leads to big energy cost reductions over extended periods.

Common Applications Across Industries

The unique capabilities of V-Type blenders make them valuable assets in numerous industrial sectors:

Pharmaceutical Manufacturing

In drug production, V-Type blenders are used for mixing active pharmaceutical ingredients with excipients, ensuring uniform distribution of medicinal compounds throughout powder formulations. Their smooth movement preserves the strength of drugs that need special handling.

Food Processing

Food manufacturers utilize V-Type blenders for creating uniform dry mixes of ingredients like spices, flavorings, and nutritional additives. The sterile equipment design serves food safety standards by keeping product mixtures separate during manufacturing cycles.

Chemical Production

Chemical companies use V-Type blenders toombine all their required dry components including powders, catalysts, and additives. The special coating on the machine seals in hazardous materials with its closed system design to produce exact mixtures at high standards.

Cosmetics Industry

For cosmetic powders, pigments, and dry formulations, V-Type blenders provide thorough mixing without compromising product texture or quality. These blenders help ensure consistent results because premium beauty product performance depends on this factor.

Agricultural Products

Fertilizer manufacturers and animal feed producers use V-Type blenders to create homogeneous mixtures of nutrients, minerals, and other dry components. The machine easily blends both small and large particle sizes.

Technical Considerations When Selecting a V-Type Blender

Multiple technical aspects must receive attention to pick the proper V-Type blender.

Material of Construction

Most industrial V-Type blenders are constructed from stainless steel, with 304 grade being common for general use and 316L preferred for corrosive applications. Several models use unique materials to function with specific substances.

Capacity Requirements

The blender system selection must cover daily output and create enough space for effective mixing processes. Buyers should choose a blender that can mix up to 20% to 30% more than their biggest batch quantity to achieve perfect mixing efficiency.

Rotation Speed Control

Variable speed drives help operators control the speed of their blend rotation for different materials. Equipment performance depends on operating speeds between 10 and 25 RPM and certain tasks require specific mixing rates.

Special Features

Based on particular product needs merchants often choose blenders featuring these extra features.

- Heating/cooling jackets for temperature-sensitive materials

- These blenders remove air or moisture from materials that demand vacuum processing

- CIP (Clean-in-Place) systems for frequent product changeovers

- Explosion-proof designs for flammable powders

Maintenance and Operational Best Practices

Proper maintenance ensures long service life and consistent performance from V-Type blenders:

Regular Inspection Routine

- Check drive components (motor, gearbox, bearings) for proper lubrication

- Check the technical condition of sealing elements and protective elements for potential defects.

- Check that the outlet valve system fulfills its intended function.

- Check if the intensifier bars display signs of breakage or excessive usage.

Cleaning Procedures

- Follow manufacturer-recommended cleaning protocols

- Follow recommended cleaning products based on what material you process

- Look closely at the seals and discharges because these areas collect residues most often

- Employee records display all cleaning results

Operational Guidelines

- Never exceed recommended fill levels

- Regularly check how long ingredients blend to stop them from being mixed too long

- Make standard work methods for each product type

- Train team members about correct material handling methods

Comparing V-Type Blenders to Other Mixer Types

While V-Type blenders excel in many applications, understanding how they compare to alternative mixer designs helps in selecting the right equipment:

Ribbon Blenders

The mixing performance of ribbon blenders depends on helical ribbons inside the tank which delivers quick material distribution. However, they may generate more heat and particle attrition compared to V-Type blenders.

Double Cone Blenders

Similar in principle to V-Type blenders but with a different geometry, double cone mixers are also gentle on materials but may have slightly different mixing characteristics and discharge patterns.

Tumble Blenders

Introduction-level tumble blenders have basic construction yet achieve less efficient blending of materials with different particle sizes or densities.

High-Shear Mixers

High-shear mixers provide effective results when working on cohesive substances or size reduction needs but they need high energy consumption and may harm breakable items.

Future Trends in V-Type Blender Technology

A combination of progressing manufacturing technology and emerging industry trends influences the current developments in V-Type blender construction as well as operational practices:

Smart Manufacturing Integration

Modern V-Type blenders increasingly incorporate IoT sensors and connectivity for real-time monitoring of parameters like torque, temperature, and mixing uniformity, enabling predictive maintenance and process optimization.

Advanced Material Science

A combination of new surface finishing methods and special alloy materials keeps developing for resistance against wear while maintaining compatibility between various applications.

Sustainability Features

Manufacturers dedicate their efforts to developing energy-saving equipment alongside recycling materials for fulfilling environmental sustainability needs in the marketplace.

Hybrid Mixing Systems

Equipment providers work on developing combination systems which merge V-Type blending units with different processing features such as drying and coating through unified installation units.

Conclusion

Vortex V-Type blenders represent a time-tested yet continually evolving solution for industrial powder and granule mixing needs. This manufacturing equipment is vital across industries because it provides a gentle yet effective blending motion combined with operational flexibility and efficiency.

The maintenance and proper selection of these blenders result in continuous production of high-quality mixed content throughout multiple batches. Manufacturers who comprehend operating principles and maintenance needs and various applications of V-Type blenders will benefit most from their equipment investments.

For operations requiring reliable dry material blending with minimal product damage and easy cleaning, V-Type blenders often prove to be the optimal choice among industrial mixing technologies.

Ask An Expert