Ask An Expert

Frequently Asked Questions

Yes, We can supply simple stand alone panels or automated PLC controlled systems. We normally install and test all controls on our mixers before they are shipped.

Yes, we normally test the mixers before they are shipped and mark out the wire need to connect on the control box.

We manufacture specialty mixing equipment for powder & bulk materials. Included are ribbon blender, plough mixer, conical screw mixer, twin shaft paddle mixer, V blender, double cone blender and other auxiliary equipment such as screw conveyor, quantitive auger filler.

We sell across the world, our cusotmers distribute 5 continents.

Share Us With Your Network

Vertical Mixers – Compact and Clean Mixing Solutions for Industrial Use

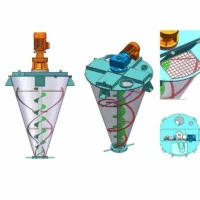

Vertical mixers find a very important application in mixing of powders, granules and feed ingredients in industries. These machines mix gently and effectively by raising material upward using an agitator and then letting gravity draw it back down. The machines do not require a large horizontal footprint. INCMachine features entire vertical series of mixers-conical screw, vertical ribbon and conical ribbon mixers-which are engineered as full-discharge and no-residue.

Vertical mixers are preferred where batch-wise mixing is required providing good control in ingredient mixing with hygienic and space efficiency advantages. They are suitable in processes that need dependable mixing in fields such as feed, food, plastics, agriculture and chemicals.

The Main Components that are shared amongst all Vertical Mixers

The models in the vertical mixer family have an important set of advantages in common:

- Full drainage ensured by vertical structure and shape of a cone

- Tight vertical design suited to facilities with a small amount of floor space

- Minimal energy needed relative to horizontal or rotary mixers

- Soft mixing that does not destroy or damage sensitive or delicate materials

- Sturdy structural material of stainless or carbon steel

- Possible extras like the weighing systems jackets, liquid injection or PLC controls

Vertical mixers types with INCMachine

- Conical Screw mixer

Conical screw mixer is a kind of mixer with a conical vessel and its screw agitator is vertically positioned. The screw moves material up the ridge towards the point of the cone once which it then free-falls over the walls. This is natural flow that allows total mixing without much shearing which is suitable when it comes to heat sensitive products, or delicate products. Its conical bottom makes it easy to clean and the entire discharge to be possible.

Areas of application: feed mixture, chemical powders, agricultural products

Benefits: a light move, complete experience, little power consumption

- Vertical Ribbon Mixer

A central ribbon-shaped agitator is being utilized in a cylindrical vertical tank in this design. The ribbon swings the materials upwards and the gravity forces them back to the bottom leading to fast upward-downward cycle mixing. Due to design, a batch mixing time is shorter compared to the conventional screw-only mixing mixers

Field of use: dry powdered preparation, food additive, pharmaceuticals

Benefits: quick mix, light on the product, fills at 10 to 90 percent fill point

- Conical Ribbon Mixer

The conical ribbon mixer combines the characteristics of the conical and the ribbon mixers. Three-dimensional mixing is performed in a ribbon agitator in a conical vessel. This brings together the practical functionality of a ribbon-type agitator coupled with the smooth nature of conical shape, which result in clean mixing devoid of residue.

Fields of activity: chemical powder feed specialty goods

Strengths: the 3D mixing, complete discharge, non-porous inner surfaces which are easily cleanable

Pros of INCMachine Vertical Mixers

Full Drain and No Residue

Every mixer ensures complete emptying and excludes the possibility of material gathering or contamination between batches.

Compact Footprint

Tall containers reduce consumption of floor space- a good feature to use during smaller plants or buildings that have height as an option but not width.

Energy Efficiency

These mixers require less power as compared to the large horizontal systems because they are low speed.

Quick Cleaning

It is easily cleaned, which is necessary in food and pharmaceutical industries due to conical bottoms and smooth interior walls making it easy to clean.

Optional Enhancements

Available options that are customizable are the heating/ cooled jacket, liquid injection lances, weighing systems, PLC panels, and CIP cleaning.

Industrial Applications

Animal Feed

Vertical mixers combine grains, protein supplements, vitamins and minerals into feed that is of high quality. Mild movement saves grain and grains.

Food Processing

Employed in Cereal blends, baked mixes, nutritional powders, spices and dry material. Ribbon and conical ribbon mixers preserve quality of ingredients.

Pharmaceutical

This is perfect to mix active ingredients and excipients. Vertical mixers guarantee the consistency of the dose and satisfy high-level hygienic demands.

Chemical Powders

Works well as a fertilizer, pigment, coating and plastic additives. The full discharge disallows cross-discharge.

Plastics

Colored or additive-filled plastic pellets also are advantageously subjected to low-shear. Vertical ribbon or conical mixers are used with this sort of blending.

Agrochemicals and Agriculture

The addition of seed coatings, fertilizers, pesticides, or feed supplements is easy and tidy, owing to complete discharge and cleanliness management.

The Proper Way to Select the Desired Vertical Mixer

- Choose the best mixer by cogitating

- Material characteristics- particle density flow behavior

- The volume of the batches and the mixing time

- Intensity of mixing required (moderate, gentle)

- Sanitation needs and rate of cleaning

- Income Available headroom vs floor space

- Non-compulsory functions such as weighing, jackets or liquid injection

INCMachine is a source of professional advice, technical specification and pilot testing that guarantees adequate mixer selection and integration

Example Comparisons

| Type of mixer | Best use | Strength |

| Conical Screw | Heat sensitive / fine powders | Low shear |

| Vertical Ribbon | Quick mix powder | Faster mixture than screw |

| Conical Ribbon | 3D mixing in conical vessel | Effective and clean work |

Advantages of INCMachine Vertical Mixers

Under the Vortex Mixing Technology, INCMachine offers versatile engineering and technical support.

The most important ones are as follows:

- Consultation services by experts and personal designs

- Worldwide shipping and installation aid

- Safety compliance and use of high quality materials

- Automatic (or optional) automation, weighing and heating installations

- Quality pricing at long lasting lifetimes

They can be combined with small feed mill or large chemical operations and in any case, they blend in very well to enhance consistency, quality and efficiency of operations.

Conclusion

Vertical mixers, are stable, and energy-saving apparatus of consistent mixing of powders, and granular items. INCMachine forms part of a range of conical screw mixers, vertical ribbon mixers and conical ribbon mixers, selected to suit special sectors and materials.

These selections allow full discharge, smooth blending, and small size. Visit Vertical Mixer category of INCMachine.com and communicate with their specialists to find a perfect mixer specially designed to fit your sector.

Ask An Expert